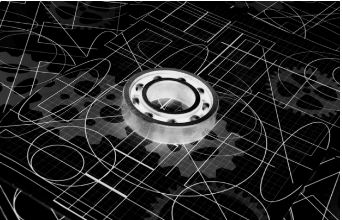

High-speed ball bearings serve as silent guardians within machinery, facilitating smooth rotation and minimizing friction. This blog aims to provide information about the multifaceted perks of ball bearings in high-speed applications, the intricacies of selecting the perfect bearings, its cost-saving benefits, and valuable maintenance tips. Join us to unlock the full potential of ball bearings and discover why choosing a reputable bearing company is paramount for success.

The Multifaceted Perks of Ball-Bearings in High-Speed

High-speed applications necessitate components capable of withstanding rigorous conditions. Ball bearings excel in this domain, offering an abundance of advantages. Firstly, they reduce friction, enhancing efficiency while minimizing wear and tear on machinery. This attribute directly translates to increased longevity and reliability, ensuring uninterrupted operations.

Moreover, ball bearings contribute to energy conservation by requiring less power to overcome frictional forces. This efficiency reduces operational costs and aligns with sustainable practices—a paramount consideration in contemporary industries. Additionally, their compact design enables streamlined construction, optimizing space utilization in complex machinery setups.

Selecting the Perfect Ball-Bearings

Choosing the appropriate ball bearings is a nuanced process that demands meticulous attention to detail. Load capacity, speed rating, and environmental conditions must be carefully evaluated. A reputable bearing company like KG International offers a comprehensive range of products tailored to diverse applications.

It is imperative to consider the specific requirements of each application when selecting ball bearings. The chosen bearings must align with the operational demands, whether high-speed machinery in manufacturing facilities or precision instruments in medical settings. Consulting with experts from a trusted company ensures informed decision-making and optimal performance. Trusted advisors can provide invaluable insights into bearing materials, lubrication requirements, and maintenance protocols, guiding customers towards the most suitable solutions for their unique needs. This collaborative approach fosters confidence in the selection process and fosters long-term partnerships built on mutual trust and satisfaction.

Saving on Maintenance Costs with Ball-Bearings

One of the most compelling advantages of utilizing high-quality ball bearings is the significant reduction in maintenance costs. Their robust construction and minimal frictional losses translate to extended service intervals and decreased downtime. This enhances operational efficiency and mitigates the financial burden associated with frequent maintenance.

Furthermore, the durability of ball bearings minimizes the need for replacement, further reducing long-term expenditures. By investing in premium-quality bearings from a reputable company, businesses can realize substantial savings over the lifecycle of their machinery. This cost-effectiveness underscores the importance of prioritizing quality and reliability in component selection.

Maintenance Tips for Ball Bearings

Proper maintenance is paramount to ensuring the longevity and performance of ball bearings. Regular lubrication is essential to minimize friction and prevent premature wear. Additionally, it is necessary to monitor for indications of damage or contamination to ensure early detection and prompt intervention.

Examining bearings for irregularities such as noise, vibration, or overheating can aid in detecting potential issues before they worsen. Cleaning bearings periodically to remove dirt and debris prevents abrasion and prolongs service life. Collaborating with a reputable bearing company for maintenance guidance and product recommendations is advisable for optimal results. Trusted advisors can offer tailored maintenance plans and recommend suitable lubricants and cleaning techniques based on specific operating conditions. This proactive maintenance approach enhances reliability and efficiency of machinery and extends the lifespan of ball bearings, thus maximizing return on investment.

Why Choose a reputable Bearing Company for Ball Bearings

Selecting the right supplier for ball bearings is paramount to ensuring quality, reliability, and customer support. KG International stands out as a premier-bearing company renowned for its extensive product portfolio, technical expertise, and commitment to customer satisfaction.

With decades of experience in the industry, KG International offers unparalleled insights into bearing selection, application optimization, and maintenance best practices. Their dedication to quality assurance and continuous improvement guarantees superior products that meet the most stringent performance standards.

Partnering with KG International offers businesses’ a peace of mind, knowing they have a trusted ally committed to their success. From initial consultation to ongoing support, their team of experts is poised to address any challenges and provide tailored solutions. Regarding ball bearings, choosing KG International is synonymous with reliability, efficiency, and excellence.

Conclusion

The importance of high-speed ball bearings cannot be overstated in the present industrial landscape. As explained, these feats of engineering play a critical role in maintaining seamless operations, reducing downtime, and enhancing efficiency. By partnering with a reputable bearing company like KG International, businesses can harness the full potential of ball bearings while enjoying unparalleled quality, reliability, and support.

Whether selecting the perfect bearings for a specific application or implementing effective maintenance strategies, KG International is a trusted partner every step of the way. With their specialized knowledge and dedication to exceptional performance, businesses can confidently navigate the intricacies of modern machinery and attain unparalleled success.