Bearings play a critical role in the dynamic and ever-evolving automotive industry, often unnoticed despite their pivotal contribution to vehicle performance. Particularly in the United Arab Emirates, a region synonymous with luxury vehicles and an expanding automotive sector, understanding the nuances of automotive bearings becomes essential. These bearings are integral to the functionality of myriad automotive components, ensuring that vehicles operate with the utmost precision and efficiency. The UAE’s market, with its unique demands and high standards, necessitates bearings that are not just durable but also impeccably designed to meet the specific needs of a diverse range of vehicles. This blog aims to provide information about Automotive Bearings in UAE, its function and significance for the automotive industry.

The Significance of Automotive Bearings

Automotive bearings hold paramount importance in vehicle mechanics, serving as the cornerstone upon which the reliability and efficiency of a vehicle rest. These components are fundamental in mitigating friction between moving parts, facilitating smooth motion, and enhancing the durability of vehicle components. The absence of high-quality bearings would precipitate a significant decrease in vehicle performance, escalating maintenance costs and diminishing the overall lifespan of automotive parts. Thus, bearings are not just mechanical components, they are the lifeline of vehicles, ensuring optimal performance while navigating the diverse and challenging terrains of the UAE.

The Function of Automotive Bearings

- Automotive bearings are vital in absorbing and managing mechanical stress, thus enabling the uninterrupted and smooth functioning of various vehicle components, enhancing the overall driving experience.

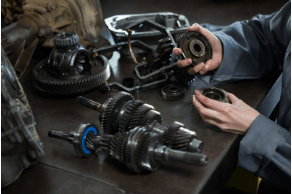

- These bearings are indispensable for the seamless operation of essential vehicle parts, including wheels, engines, and transmissions, which are crucial for the mobility and power of the vehicle.

- Integral to nearly every mechanical aspect within a vehicle, bearings ensure the reliability and efficiency of the automotive machinery, contributing significantly to the operational integrity of the vehicle.

- Designed to withstand significant stress levels, automotive bearings are crucial in extending the durability and longevity of the vehicle, protecting it from premature wear and potential failures.

- Whether a vehicle travels on smooth highways or navigates challenging, rugged terrains, the bearings ensure consistent and reliable performance, adapting to varying conditions.

- The precision involved in manufacturing automotive bearings is a critical factor that directly impacts the efficiency and smooth operation of the vehicle, reflecting the importance of quality craftsmanship.

- Bearings are vital in reducing friction and wear and essential for maintaining the long-term health and performance of the vehicle. This reduction in wear and tear decreases the necessity for regular maintenance, thereby prolonging the life of the parts.

- Their significant role in enhancing vehicle performance underscores the connection between expertly engineered bearings and the effectiveness of automotive systems, illustrating the critical nature of bearings in automotive design and function.

UAE Bearings Market – Export Market Opportunities

The United Arab Emirates stands as a beacon in the automotive sector, not just as a consumer market but also as a pivotal player in the automotive parts industry. In the UAE, the bearings market offers diverse export possibilities, acting as a crucial access point to markets in the Middle East. The strategic geographical location of UAE, with its robust infrastructure and business-friendly environment, offers an advantageous platform for manufacturers and suppliers to expand their reach beyond the local market. The potential for growth in the UAE bearings market is immense, driven by the ongoing investments in automotive manufacturing and the increasing demand for high-quality automotive parts.

Extensive Range of KG Bearings for the Automotive Industry

KG International stands at the forefront of the automotive bearings sector in the UAE, offering an extensive portfolio of bearings that cater to a myriad of automotive applications. The offerings of the company span a wide range, accommodating the needs of passenger vehicles, commercial trucks, and specialized automotive machinery. The commitment of KG to excellence is evident in the quality of its bearings, each meticulously designed to enhance vehicle performance and longevity. The understanding of the automotive landscape in the UAE, coupled with its dedication to innovation, positions KG as a pivotal player in the bearings market, offering solutions that are not just products but pivotal components that drive the automotive industry forward.

KG is the Preferred Choice for Automotive Bearings in the UAE

In the competitive landscape of the automotive bearings market in UAE, KG International distinguishes itself with its unwavering commitment to quality and reliability. The reputation of the company as a trusted supplier of automotive bearings is built on a foundation of technical expertise and customer-centric service. Automotive professionals and enthusiasts alike turn to KG for bearings that promise durability and performance.

The trust placed in the products of KG is a testament to the dedication of the company to upholding the highest standards of quality and its deep understanding about the requirements of automotive industry in UAE.

Commitment of KG International to Quality and Trust

KG International is centered on delivering products and services that resonate with quality and reliability. Their extensive experience in the bearings industry is complemented by their expertise, which collectively ensures that offerings of KG are not just products but solutions that customers can rely on. This commitment to quality and trust sets KG apart in the automotive bearings market of UAE, fostering a relationship with customers built on mutual respect and a deep understanding of their needs.

Conclusion

Opting for KG International for your automotive bearing in the UAE is a choice that signifies a preference for excellence, reliability, and expertise. The comprehensive range of bearings, commitment to customer satisfaction, and technical process ensure that your vehicles operate at their peak performance. For those navigating the automotive landscape in the UAE, KG International offers a partnership that is synonymous with trust and quality, ensuring that your automotive journey is smooth and efficient.

To explore KG International array of automotive bearing solutions and learn how they can contribute to your vehicle’s enhanced performance and longevity, visit www.kginternational.com.