When ensuring your truck runs smoothly, one vital component is the fuel filter. Understanding the significance of fuel filters is paramount for every truck owner or operator. KG International stands out as a leader in providing top-notch fuel filtration solutions, ensuring optimal performance for your vehicle throughout its journey.

Understanding Fuel Filters

Fuel filters are gatekeepers, preventing impurities and contaminants from reaching your engine. They strain out dirt, rust particles, and other debris that could risk the efficiency and longevity of your engine. These filters play an essential role in maintaining the cleanliness of your fuel system, safeguarding critical components from damage.

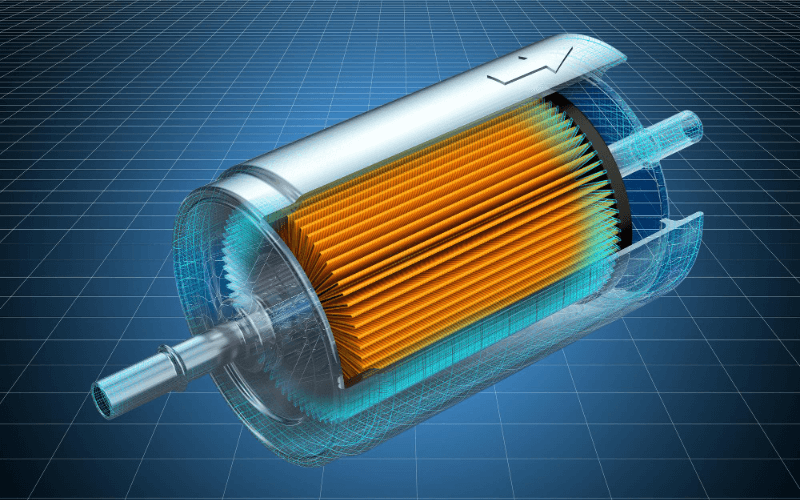

Understanding the intricacies of fuel filters involves grasping their internal structure and filtering mechanisms. Typically, a fuel filter consists of a casing housing a filter media, which traps contaminants while allowing clean fuel to pass through. This simple yet effective design ensures that only the purest fuel enters your engine, optimizing its performance.

The Role and Function of Fuel Filters

Fuel filters ensure clean fuel flows through the engine. By trapping harmful particles, they prevent clogs in fuel injectors, maintaining consistent fuel flow and combustion. This process ensures smooth engine operation and optimal fuel efficiency, ultimately prolonging the life of your engine.

Without fuel filters, your engine would be susceptible to damage from impurities present in the fuel. These contaminants can lead to corrosion of engine components, reduced fuel efficiency, and even engine failure. By effectively removing these impurities, these filters serve as a critical line of defense, preserving the integrity and performance of your engine.

The Need for Fuel Filters in the Truck Journey

Truck journeys often entail traversing diverse terrains and encountering various fuel sources. This diversity increases the likelihood of fuel contamination, making fuel filters indispensable. They protect your engine from potential damage caused by impurities, ensuring uninterrupted performance throughout your journey.

Fuel quality can vary significantly in the harsh environments often encountered during truck journeys. From dusty roads to remote gas stations, the fuel your truck encounters may contain many contaminants. Without effective filtering, these dirt particles could cause significant problems for your engine, resulting in expensive fixes and downtime. Therefore, equipping your truck with high-quality fuel filters is essential for safeguarding its engine and ensuring reliability on the road. Whether you are hauling cargo cross-country or navigating urban streets, the need for effective filtration remains constant. With dependable fuel filters, you can mitigate the risks associated with fuel contamination, ensuring smooth operation and longevity of the engine.

Importance of Regular Fuel Filter Maintenance

Regular maintenance of these filters is paramount to ensure their effectiveness. Over time, filters accumulate debris, reducing their efficiency and potentially causing engine problems. Following a regular maintenance schedule can help avoid expensive repairs and keep your engine running at its best.

Maintaining clean and adequately functioning fuel filters is essential for engine performance and efficiency. When filters become clogged, they restrict fuel flow, requiring the engine to exert more effort and consume more fuel. Regularly changing fuel filters guarantees that your engine runs at its best, saving you money on fuel expenses. Additionally, clean fuel filters contribute to reduced emissions, promoting environmental sustainability. Consistently keeping your fuel system clean also decreases the likelihood of sudden breakdowns, offering reassurance during your journeys.

When To Change a Fuel Filter

Knowing when to change your fuel filter is crucial for preserving engine health. Signs such as decreased fuel efficiency, engine misfires, and difficulty starting the engine indicate a clogged filter. Following manufacturer recommendations or scheduling replacements every 10,000 to 15,000 miles can help prevent potential issues.

Regularly monitoring your fuel filter and engine performance can help you identify the right time for a replacement. Moreover, if you work in incredibly dusty or dirty conditions, you might have to replace your filter more often to keep your truck running smoothly. Investing in quality filters and adhering to a proactive maintenance schedule can help ensure smooth operation and longevity for your engine.

KG International: Role in Fuel Filtration Excellence

KG International stands at the forefront of fuel filtration excellence, providing innovative solutions tailored to meet the needs of modern vehicles. With a commitment to quality and reliability, KG International ensures that every fuel filter delivers optimal performance, protecting your engine and maximizing fuel efficiency.

Conclusion

Fuel filters are critical in safeguarding your engine against impurities and contaminants, ensuring optimal performance throughout your journey. With excellent commitment from KG, you can trust that your fuel filtration needs are in good hands.