Thrust ball bearings are essential components in various industrial applications, pivotal in precisely managing axial loads. These specialized bearings are engineered to withstand high thrust forces while facilitating smooth rotational motion. This detailed blog aims to provide information about thrust ball bearings, examining their applications, functionalities, and the critical process of selecting the correct bearing for specific industrial needs.

Understanding Thrust Ball Bearings

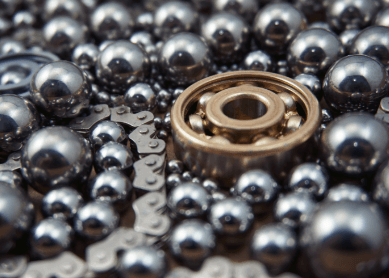

Thrust ball-bearings, or axial bearings, are meticulously engineered components designed to support axial loads predominantly in one direction. Their construction typically comprises rolling elements housed within a cage, facilitating the efficient accommodation of high-thrust loads while minimizing friction. This unique design allows them to thrive in high-speed applications, rendering them indispensable across multiple industries where precision, reliability, and durability are essential.

From automotive to aerospace, these proven bearings play a critical role in ensuring smooth and efficient operation across diverse industrial sectors.

Applications of Thrust Ball-Bearings

The versatility of these bearings makes them indispensable across various industries, including automotive, aerospace, marine, and manufacturing. Within the automotive sector, these bearings are vital components in gearboxes, transmissions, and wheel hubs, offering essential support against the axial forces experienced during vehicle operation. Likewise, in aerospace and marine applications, these proven bearings play a pivotal role in ensuring the seamless operation of control surfaces, propeller shafts, and other critical systems, where precision and reliability are paramount. Additionally, in the manufacturing industry, these bearings find application in machinery and equipment where axial loads need to be managed efficiently. Their ability to withstand high thrust forces while maintaining low friction makes them ideal for various industrial applications, contributing to enhanced performance and productivity across multiple sectors.

Managing Axial Loads with Precision

Precise axial load management is a hallmark characteristic of thrust ball bearings. These components effectively minimize wear and guarantee consistent performance over prolonged periods through the even distribution of loads across bearing surfaces. This capability is vital in industries where reliability and longevity are critical for operational success.

Advanced designs of these bearings go beyond essential load management. They integrate features such as precision-ground balls and raceways, elevating their load-bearing capacity and overall durability. These enhancements ensure the seamless operation of machinery and contribute significantly to the extended service life of the bearings. By continually refining and advancing their designs, manufacturers strive to meet the evolving needs of various industries, reinforcing the pivotal role of these proven bearings in modern industrial applications.

Thrust Ball Bearings for Specialized Industrial Applications

The requirements for thrust ball-bearings are exceptionally stringent in specialized industrial sectors such as mining, oil and gas, and heavy machinery. These industries impose rigorous demands on bearing solutions, necessitating components capable of enduring extreme operating conditions. From coping with high loads to mitigating shock and thriving in harsh environments, these bearings must meet diverse challenges head-on to ensure uninterrupted operations.

Custom-designed bearings emerge as indispensable assets in addressing these unique challenges. Customized to address individual applications’ requirements, these bearings offer specialized solutions that prioritize reliability, efficiency, and extended longevity. By collaborating closely with engineers and bearing specialists, industries can access delivering solutions meticulously crafted to excel in their respective environments, thereby enhancing productivity and minimizing downtime.

The Pivotal Role of Thrust Ball Bearings in Various Applications

These bearings are essential in numerous applications where precision, reliability, and durability are crucial. These bearings enable smooth and efficient operation across diverse industrial sectors, from heavy-duty machinery to precision instruments. Their versatility and performance make them essential for achieving optimal functionality and productivity in demanding environments.

Selecting the Right Thrust Ball Bearing

Choosing the appropriate thrust ball-bearing is paramount for achieving optimal performance and longevity in industrial applications. Various factors come into play during the selection process, including load capacity, operating speed, temperature range, and environmental conditions. Each of these factors must be meticulously evaluated to ensure the chosen bearing can withstand the demands of its intended application.

Collaborating with experienced engineers and bearing specialists is highly beneficial in navigating the complexities of delivering selection. Their expertise and insights can help identify the most suitable bearing solution tailored to the requirements of application. By leveraging their knowledge, industries can ensure optimal performance and cost-effectiveness in the long run. This cooperative method simplifies the selection process, reducing the likelihood of errors and optimizing industrial operation efficiency.

Conclusion

Thrust ball-bearings are indispensable components across various industrial sectors, ensuring precision, reliability, and durability in managing axial loads. Customized solutions are designed to meet specialized industrial needs, optimize performance and efficiency, and contribute significantly to increased productivity and profitability. Industries can elevate operational performance and ensure long-term reliability by carefully selecting the appropriate thrust ball bearing for specific applications. To explore a wide range of these proven bearings tailored to your industrial requirements, visit KG International at www.kginternational.com.