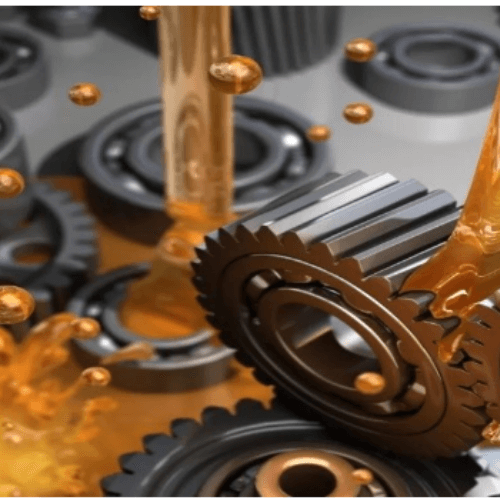

Bearing lubrication is essential for maintaining the efficiency and longevity of rolling element bearings. It is a protective layer between moving parts like rollers and raceways, minimizing friction and wear. While some may dismiss it as a messy task, it’s a pivotal technology for modern manufacturing. Inadequate lubrication is a leading cause of bearing failure. Proper bearing lubrication offers multiple benefits, ensuring optimal bearing performance. Recognizing the importance of Bearings and Housings, KG International has crafted a comprehensive guide on the subject. This guide delves into various lubricants, best practices for bearing lubrication, application procedures, and common mistakes that could jeopardize your bearings’ lifespan. Let’s begin by exploring the different types of bearing lubricants available today.

Understanding Different Types of Lubricants

When it comes to lubricants, there’s a lot to consider. Whether you’re dealing with machinery, vehicles, or any other equipment, choosing the proper oil can significantly affect performance and longevity.

Oil vs. Grease: The Basics

There are two primary types of lubricants available: oil and grease. The choice between them isn’t arbitrary; it hinges on several factors:

There are two primary types of lubricants available: oil and grease. The choice between them isn’t arbitrary; it hinges on several factors:

– The machinery in question and its specific components, like the bearing type.

– The size, temperature, and speed range of the machine.

– Load conditions and other operating specifics include vibrations and the shaft’s orientation.

– The external environment might expose the machinery to contaminants or corrosion.

Why Lubricate?

Lubricants serve several essential functions:

Lubricants serve several essential functions:

– They guard surfaces against rust and corrosion.

– They seal out harmful contaminants.

– They reduce friction by creating a barrier between moving parts.

– They aid in heat transfer, helping to regulate temperature

Choosing the Right Grease

Selecting the perfect grease for your bearing can be challenging. While the manufacturer’s recommendations are a great starting point, other considerations exist. For instance, bearings tend to operate most efficiently when lubricated with just enough of the lightest possible lubricant to keep their surfaces separate. The “splash method,” where oil is spread through wicking or submersion, exemplifies this principle.

However, in some situations, a denser lubricant might be necessary:

– The operating conditions demand it.

– The specific application prescribes it.

– The existing lubricant can’t handle the load.

Diving into Oil Lubricants

Lubricants serve several essential functions:

Oil lubricants are typically reserved for high-speed or high-temperature situations. They’re excellent at transferring heat away from active bearing surfaces. These oils can be natural or synthetic, like mineral oil with rust and oxidation inhibitors.

Commonly used oils include:

– Petroleum oils

– Diesters

– Silicones

– Fluorocarbons

Different oil systems, like bath, splash, air/oil mist, and jet, cater to these oils. Synthetic oils often have bases like polyalphaolefins (PAO), polyalkylene glycols (PAG), esters, or silicones suitable for colder, low-torque conditions.

It’s essential to note that while mineral and synthetic oils might seem similar, they have distinct properties and aren’t interchangeable. And among all the properties, viscosity stands out. Think of low-viscosity fluids as watery and high-viscosity as thick as syrup. The viscosity determines the thickness of the protective film the oil forms, which is crucial for separating moving parts in a bearing.

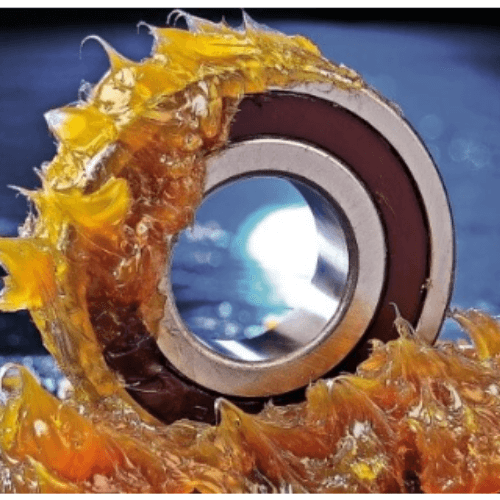

The World of Grease Lubricants

While oil has its place, grease is the go-to lubricant for 80-90% of bearings. Why? Grease sticks to bearing surfaces better, lasts longer, and doesn’t easily get thrown off by rotating parts. You can pre-lubricate with grease, reducing the need for external systems and future maintenance.

While oil has its place, grease is the go-to lubricant for 80-90% of bearings. Why? Grease sticks to bearing surfaces better, lasts longer, and doesn’t easily get thrown off by rotating parts. You can pre-lubricate with grease, reducing the need for external systems and future maintenance.

Grease lubricants comprise three main components:

– Additives, often to prevent rust.

– A base oil.

– A thickener.

When picking grease, remember that the base oil’s viscosity is pivotal in determining how the lubricating film forms.

Maintenance is Key

No matter your choice of lubricant, it won’t last forever. Over time, its lubricating properties will wane. With proper upkeep and expert lubrication services, bearings can succeed. Lubrication is crucial for the performance and longevity of bearings, ensuring moving parts remain separate, reducing friction, and preventing wear.

How can you tell if your bearings are being lubricated correctly?

Well, it’s essential to choose the proper lubricant for the job, apply it the right way, and adhere to a maintenance schedule tailored to your equipment. Though it might sound straightforward, many need to pay more attention to the specifics, leading to poor lubrication practices in many facilities and, consequently, bearing failures.

Here’s a breakdown of common lubrication-related reasons for bearing failures:

- Lubricant Depletion: If you don’t re-grease bearings at the proper intervals using the correct amount, they can lose their lubrication, leading to equipment breakdown.

- Using the Wrong Grease: Matching the grease to the job is vital. For instance, while some tasks might need general-purpose oil, others might require a specialized type, like extreme pressure grease, as pointed out by machinery lubrication.

- Over-lubrication: Too much grease can cause bearings, incredibly open to face overheat.

- Grease Breakdown: Over time, grease can degrade in various ways, such as the oil separating from its base, chemical decomposition from high temperatures, or the fat becoming too complicated.

- Incompatible Greases: Always ensure you’re using the same type of grease or a compatible alternative throughout a bearing’s lifespan. Remember, not all greases play well together.

Lastly, how you apply the lubricant is just as crucial as picking the right one. Key steps include cleaning the bearing, ensuring the lubricant is of good quality, and adequately running in the bearing.

If you still have questions regarding efficient bearing lubrication for your business needs, please get in touch with KG International, and we will guide you through appropriate lubrication solutions.