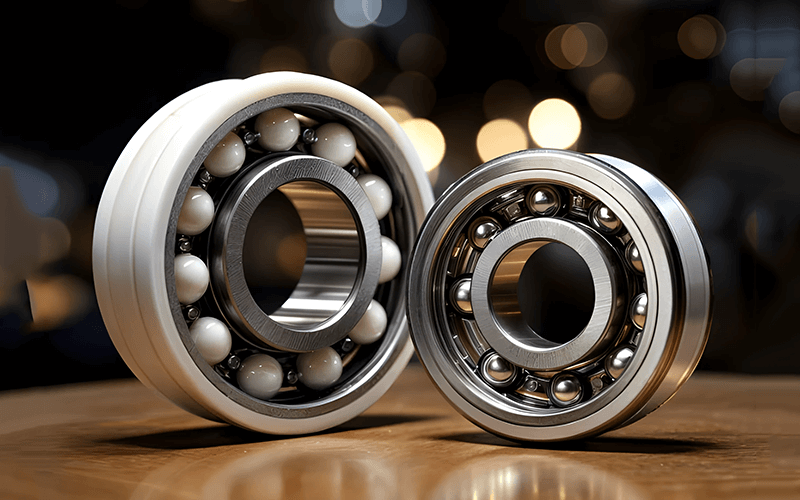

Ball bearings are crucial components essential to operating various machines, instruments, and vehicles, and they are pivotal in promoting smooth and efficient functioning across numerous industries. They facilitate reduced friction and enhanced mobility, which is critical for optimal performance. This blog aims to provide information about the differences and distinct advantages of ceramic versus steel ball bearings, offering insights into how each type influences the efficiency, durability, and overall performance of machinery. By understanding these fundamental differences, you can better assess which type of bearing will best meet the specific needs of your applications.

The Importance of Ball Bearings

Ball bearings are vital in the mechanical industry, as they greatly minimize rotational friction and robustly support radial and axial loads in diverse machinery. These components are essential for enabling parts within machines to move freely and smoothly, which is vital for both the efficiency and longevity of moving assemblies. Found ubiquitously in devices ranging from simple household appliances to complex industrial machinery, ball bearings are small yet powerful components whose performance can profoundly affect the overall functionality and durability of any system.

Their ability to facilitate seamless motion makes them indispensable in enhancing operational reliability and efficiency across numerous applications.

Ceramic vs. Steel Ball Bearings: Key Differences

Friction and Efficiency: Ceramic ball bearings are superior in construction and material properties. The balls in these bearings are rounder, lighter, and smoother than those in steel bearings, reducing friction and energy loss. This improvement means equipment can operate more efficiently and endure more extended operational periods with minimal maintenance due to the reduced need for lubrication.

Resistance to Corrosion: Unlike steel ball bearings, ceramic types do not suffer from corrosion. This non-corrosive nature makes ceramic hybrid ball bearings up to ten times more durable against corrosion-related wear and tear.

Impact on Bearing Races: Despite their advantages, ceramic ball bearings have a warning regarding their elasticity — they are significantly less elastic than steel. This can be a drawback under heavy spindle loads or accidental spindle crashes, potentially leading to quicker damage or ‘brinelling’ of the bearing raceways.

Electrical and Magnetic Conductivity: Ceramic bearings are non-magnetic and non-conductive, making them ideal for applications where electrical or magnetic interference is a concern, such as in electric motors controlled by variable frequency drives.

Thermal and Dimensional Stability: Precision is vital in applications requiring high-speed operations. Ceramic bearings are advantageous here, as they exhibit minimal thermal expansion compared to steel bearings, thus maintaining more consistent performance at varying temperatures.

Cost Considerations: Ceramic bearings typically cost about 50% more than steel counterparts. The choice between the two often concerns specific application needs versus budget constraints.

When to opt for Ceramic vs. Steel Ball Bearings

Ceramic Bearings: These are preferable for applications demanding high speed, load capacities, and temperature tolerance. They are also beneficial when increasing axial and radial stiffness without compromising speed or in environments where electrical conductivity could pose operational challenges.

Steel Bearings: These are chosen when cost considerations are paramount or when applications benefit from the inherent elasticity of steel. They are also favored for quicker turnaround needs in maintenance or part replacement situations.

Why Ceramic Ball Bearings Are Essential

Ceramic ball bearings are essential for high-performance applications primarily because of their remarkable ability to handle higher speeds and heavier loads with significantly reduced friction and wear. These bearings are constructed from advanced ceramic materials, which grant them superior durability and resistance to various environmental factors. Notably, they withstand temperature fluctuations and corrosion far better than traditional materials, making them highly valuable in industries where operational conditions can be extreme.

Furthermore, their resistance to deformation under stress and their ability to maintain integrity in challenging environments extend the operational life of machinery, ensuring more reliable and consistent performance. This combination of traits makes ceramic ball bearings a critical component in achieving efficiency and longevity in demanding applications.

Critical Advantages of Ceramic Over Steel Bearings

- Reduced Rolling Resistance: The surface finish of ceramic bearings is exceptionally smooth and uniform, which decreases rolling resistance.

- Lightweight Design: Ceramic bearings are lighter than steel, enhancing overall performance.

- Enhanced Durability: The hardness of ceramic materials makes these bearings more resistant to wear and tear.

- Increased Stiffness: Ceramic balls deflect less under load, maintaining better precision under high-load conditions.

- Speed Benefits: Their ability to handle higher speeds without significant heat generation makes ceramic bearings a preferred choice for many manufacturers.

Conclusion

Understanding the essential roles and advantages of various ball bearings, mainly ceramic and steel, enables businesses to make knowledgeable choices about the best components for their machinery. KG International offers diverse steel ball bearing solutions, including deep groove ball bearings, angular contact ball bearings, and Thrust ball bearings, catering to various industrial needs. KG International provides high-quality options to meet your requirements. Their expertise in superior bearing solutions ensures that you receive the best products, comprehensive support, and service. Explore the range at KG International and find the perfect match for your application.