The proliferation of fake ball bearings in the international market presents a significant issue, impacting numerous sectors that depend on these essential elements. The rise in global commerce and the emergence of online platforms have contributed to the increasing presence of these counterfeit items. Imitators strive to replicate the look and branding of established bearing producers, complicating the task for purchasers to differentiate real products from imitations.

The presence of counterfeit bearings is a matter of concern for manufacturers, distributors, and end-users due to the substantial risks they carry. To guarantee the safety, dependability, and functionality of equipment, it’s crucial to source bearings from trustworthy producers and distributors and to authenticate the products through reliable means.

The dangers of counterfeit bearings include:

The dangers of counterfeit bearings are multifaceted and significant, impacting various aspects of operations and safety. These include:

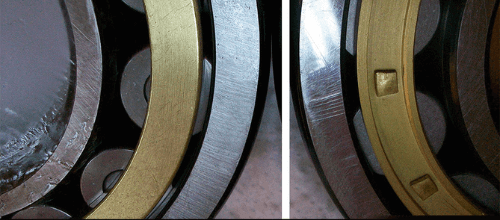

Compromised Quality and Reliability: Counterfeit bearings are often manufactured using inferior materials and lack the rigorous quality control processes that genuine bearings undergo. This results in a product that is less reliable and more prone to failure. The use of such bearings can lead to frequent breakdowns and reduced lifespan of machinery, affecting overall operational efficiency.

Increased Risk of Equipment Failure: These bearings may not meet essential design specifications or industry standards. In sectors where accuracy and longevity are essential, like in heavy machinery or automotive fields, employing counterfeit bearings increases the probability of equipment malfunction. This situation presents not just a hazard to the equipment itself but also poses potential risks to the safety of those operating and working on the machinery.

Safety Hazards: In high-speed or high-load applications, the failure of a counterfeit bearing can have catastrophic consequences, including serious injury or even fatalities. The inability of these bearings to perform under stress can lead to accidents, posing significant safety hazards in industrial environments.

Economic Impacts: The use of counterfeit bearings can result in increased maintenance costs due to more frequent replacements and repairs. Additionally, equipment downtime caused by bearing failures can lead to significant losses in productivity and revenue, especially in sectors where continuous operation is crucial.

Damage to Equipment: Counterfeit bearings are not designed to withstand the same levels of stress and load as their genuine counterparts. This can result in undue wear and tear on equipment, leading to premature damage and potentially costly repairs or replacements.

Legal and Warranty Issues: Using counterfeit bearings can void warranties on machinery and equipment. Furthermore, if a counterfeit bearing causes damage or injury, it can lead to legal complications and liability issues for the parties involved, including manufacturers, distributors, and end-users.

In a nutshell, the risks associated with counterfeit bearings extend beyond mere financial loss, encompassing safety concerns, legal liabilities, and significant operational disruptions. It is therefore crucial for stakeholders to ensure the authenticity of bearings to maintain safety, efficiency, and reliability in their operations.

Detecting Counterfeit Bearings:

Performance Testing: A counterfeit bearing might show lower performance, such as reduced load capacity or shorter lifespan. Performance tests can uncover any irregularities.

Weight Check: Authentic bearings are made to specific weight and tolerance levels. A bearing that seems unusually light or heavy might be counterfeit. Visual Inspection: Counterfeit bearings may exhibit poor logo printing, inconsistent colors, or uneven surfaces, unlike genuine bearings, which are typically made with high precision and uniform appearance.

Source Verification: Buying from reputable suppliers or manufacturers helps ensure authenticity. If in doubt about a supplier, checking their reputation and customer feedback is advisable.

It’s vital to exercise caution when purchasing bearings and to confirm their authenticity for meeting specific needs and ensuring reliable performance.

Market Impact of Counterfeit Bearings:

Safety Concerns: Counterfeit bearings not meeting industry standards or quality benchmarks can pose safety risks, leading to product recalls, liability claims, and damage to the reputation of manufacturers and suppliers.

Reduced Efficiency: With lower carrying capacity, shorter lifespan, or diminished performance, counterfeit bearings can increase maintenance costs, downtime, and equipment failure, affecting productivity and profitability.

Supply Chain Disruption: Counterfeit bearings can infiltrate the supply chain at various stages, causing disruptions, delays, and increased costs.

Revenue Loss: Sold at lower prices, counterfeit bearings can lead to revenue loss for genuine manufacturers and suppliers, affecting their profit margins.

Combating Counterfeit Bearings:

Anti-Counterfeit Technologies: Bearing manufacturers are implementing technologies like holograms, unique markings, or embedded microchips to distinguish their genuine products.

Supply Chain Audits: Regular audits help ensure product authenticity and prevent counterfeits from entering the market.

Awareness Campaigns: Manufacturers are educating the public about the risks of counterfeit bearings and promoting the purchase of genuine products through industry associations and regulatory bodies.

With KG International, you can be sure of authentic bearings. Contact us now to discuss your project requriements. We have 53+ years of experience in delivering the highest quality bearings as we have partnered with the most prominent bearing manufacturers and ensured an effective distribution channel throughout a variety of businesses.