In the dynamic and competitive industrial environment of the United Arab Emirates (UAE), identifying the most reliable ball-bearing suppliers is a pivotal concern for businesses across many sectors. Ball bearings are considered the backbone of mechanical applications. These play an indispensable role in enhancing the efficiency and durability of machinery. This blog aims to discuss the essence of ball bearings, underscoring their significance across various industries. Let’s explore the diversity of types available and outline the essential considerations for selecting the right supplier in the UAE.

The Critical Role of Ball Bearings in Diverse Sectors

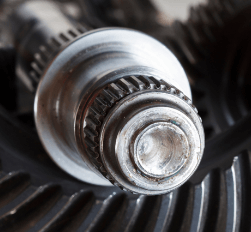

Ball bearings are fundamental to operating a wide range of machinery, facilitating reduced friction and smoother motion between moving parts. Their application spans several industries, including but not limited to automotive, aerospace, electronics, and heavy machinery. In the automotive sector, ball bearings are crucial for the optimal performance of wheels, engines, and transmissions. Similarly, in manufacturing, they are critical to the efficient operation of conveyor systems, robotics, and assembly lines.

The universal applicability and efficiency of ball bearings make the selection of a supplier a strategic decision for businesses. In the renewable energy sector, ball bearings play a crucial role in wind turbines, enabling the turbine blades to rotate smoothly and efficiently. In the medical field, precision ball bearings are used in equipment such as MRI machines, where high-speed and low-noise operation is essential.

A Closer Look at the Types of Ball Bearings

The ball bearing market is characterized by its variety, with each type designed to cater to specific operational needs and conditions. The primary categories include:

- Deep Groove Ball Bearings: These are designed for versatility and efficiently handle radial and moderate axial loads. They are known for their durability and are widely used in many applications.

- Angular Contact Ball Bearings: These types accommodate higher axial and radial loads and are suitable for high-speed applications, offering superior precision.

- Self-aligning Ball Bearings: With the ability to compensate for misalignment, these bearings are suitable for scenarios where shaft and housing alignment is challenging.

- Thrust Ball Bearings: Focused on handling axial loads, thrust ball bearings are utilized in applications where the primary load is parallel to the shaft.

Selecting the Right Ball Bearings for Your Business Needs

Choosing the ball bearing suppliers in UAE is crucial for ensuring operational efficiency and machinery reliability. Considerations include:

- Application Specifics: Understanding the unique requirements of your application, such as load, speed, and precision, is essential.

- Material and Quality: Opting for bearings made from high-quality materials can significantly enhance their performance and lifespan.

Finding the Best Ball Bearing Suppliers in UAE

The search for the most reliable ball bearing suppliers in the UAE requires thorough research and consideration of several factors, including the product range, quality certifications, supply chain efficiency, and customer support capabilities. It is beneficial to partner with suppliers who possess a profound understanding of the local market dynamics and can offer customized solutions to meet specific business needs.

KG International: A Leading Name in Ball Bearing Supply

KG International stands out as a premier supplier of ball bearings in the UAE, boasting an extensive selection of top-quality bearings suitable for a wide array of applications. Their commitment to excellence, combined with an in-depth knowledge of the industrial landscape, enables them to fulfil the varied requirements of businesses across different sectors.

Conclusion

The strategic selection of ball bearing suppliers in UAE is a critical decision that can significantly influence the efficiency and success of business operations. Understanding the types of ball bearings, their applications, and the factors to consider when choosing a supplier are critical steps in navigating the market effectively. KG International, with its comprehensive product range, commitment to quality, and exceptional customer service, stands as a leading supplier capable of meeting the diverse needs of businesses across the UAE.

In the ever-evolving industrial landscape, the importance of reliable ball bearings and the choice of the right supplier cannot be overstated. KG International offers the expertise, product range, and support needed to ensure your equipment components operate flawlessly, supporting your operations and contributing to your success in the competitive UAE market.