UAE auto sector looks to end year on high note | Business – Gulf NewsThe United Arab Emirates (UAE) has rapidly evolved into a hub for the automotive industry, with a burgeoning auto sector that demands high-performance components to keep the wheels of progress turning. One such indispensable component is the automotive bearing. These unassuming yet vital components play a pivotal role in ensuring the efficiency, safety, and reliability of vehicles.

UAE auto sector looks to end year on high note | Business – Gulf NewsThe United Arab Emirates (UAE) has rapidly evolved into a hub for the automotive industry, with a burgeoning auto sector that demands high-performance components to keep the wheels of progress turning. One such indispensable component is the automotive bearing. These unassuming yet vital components play a pivotal role in ensuring the efficiency, safety, and reliability of vehicles.

The United Arab Emirates (UAE) is a land of towering skyscrapers and opulent lifestyles as much as it is a region where the automotive industry has undergone a remarkable and transformative journey. This blog invites you to embark on a captivating voyage through the evolution of the UAE’s automotive sector – a journey that traces its roots from revolutionary beginnings to its current status as a dynamic and forward-thinking participant in the global automotive arena.

The Early Days: Automotive Beginnings in the UAE

Transport yourself back in time to explore the modest origins of the UAE’s automotive industry. Discover how the seeds of passion for automobiles were sown in the hearts of the people and witness the first automobiles that graced the streets of the UAE’s major cities. This is a story of transition, where traditional camels shared the road with modern vehicles, setting the stage for a remarkable automotive revolution.

Stay tuned as we continue this journey through the automotive history, uncovering more chapters of growth, innovation, and transformation. In this blog, we explore the future of automotive bearings in the dynamic auto sector, shedding light on their significance, evolving technologies, and the role of KG International in meeting industrial needs.

The Significance of Automotive Bearings

Automotive bearings are mechanical marvels that reduce friction and enable smooth motion within various vehicle components. They are found in critical areas like wheels, axles, transmissions, and engines. Bearings contribute to enhanced fuel efficiency, reduced emissions, and improved vehicle performance, making them an essential part of modern automotive engineering.

Evolving Technologies

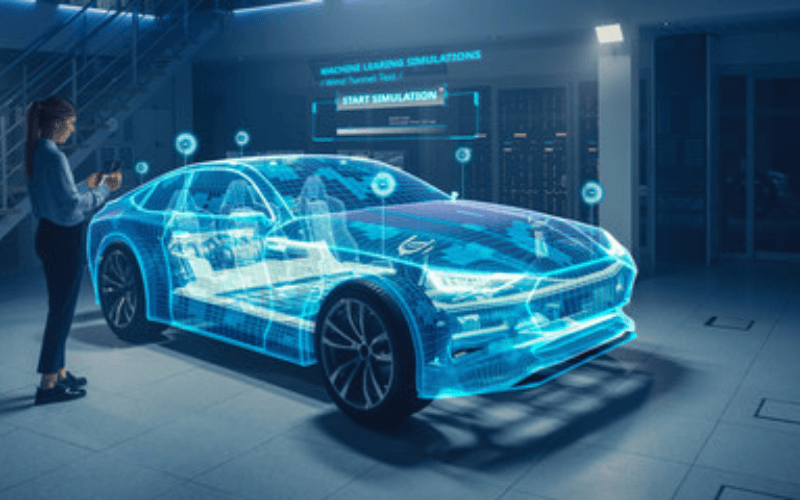

As the automotive industry undergoes a transformative shift towards electric or autonomous vehicles, the demand for advanced bearings has surged. Electric vehicles (EVs), in particular, require specialized bearings for their electric motors and drivetrains. These bearings must handle higher RPMs and torque while maintaining exceptional efficiency.

Furthermore, autonomous vehicles demand a higher degree of reliability and durability from their bearings, as they operate continuously and often under challenging conditions. Bearing manufacturers are responding with innovations such as stainless steel and ceramic bearings, which offer reduced weight and increased efficiency.

The Role of KG International

KG International, with its decades of experience in the bearing industry, is at the forefront of providing cutting-edge solutions to the UAE auto sector. Our product portfolio encompasses a wider variety of automotive bearings, each designed to meet evolving industrial needs. Whether it’s precision-engineered wheel bearings for enhanced safety or specialized bearings for electric vehicle applications, we prioritize quality, reliability, and performance.

Sustainable Practices

In line with global trends, the UAE auto sector is increasingly focused on sustainability. This shift towards eco-friendliness extends to automotive bearings, where there’s a growing emphasis on developing bearings that reduce friction, enhance fuel efficiency, and ultimately contribute to lower emissions. KG International is committed to sustainability and offers a range of environment-friendly bearings that align with the green aspiration of the UAE automotive industry.

The Road Ahead

In this thriving landscape, automotive bearings emerge as the silent yet indispensable heroes, diligently driving the wheels of efficiency, safety, and performance. These unassuming components bear the weight of the industrial ambitions, ensuring every vehicle on the road operates seamlessly and reliably.

As the automotive industry in the UAE continues to evolve, the demand for innovation becomes more pressing than ever. Technological advancements, changing regulations, and evolving consumer preferences shape the path forward, and in this dynamic environment, the automotive bearings that underpin the sector must also adapt.

It is here that KG International takes centre stage. With a legacy of excellence and a commitment to innovation, KG International is a steadfast partner for the UAE automotive industry. As challenges arise and new opportunities emerge, KG International is at the forefront, ready to provide cutting-edge solutions that empower the sector to thrive.

In essence, automotive bearings are not merely components within a machine; they are the unsung heroes that enable progress and drive the UAE auto sector toward a future defined by efficiency, safety, and peak performance.